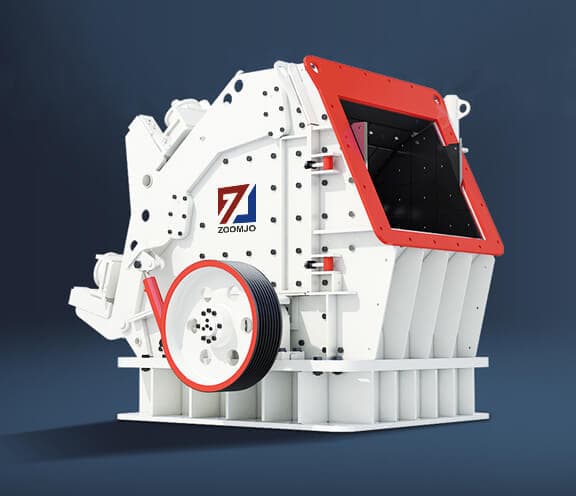

It can crush all kinds of coarse, medium and fine materials with feed size≤500mm and compressive strength≤350MPa(Granite,limestone,concrete,etc.)

The impact crusher is the latest generation of impact crusher developed by our company in the absorption of advanced technology at home and abroad,combined with the specific industrial and mining conditions of the domestic sand and gravel industry. Impact crusher are mostly used as secondary crusher and it well fits for crushing numerous medium and soft mineral &rock materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, and graphite, et

Durable wearing parts, stable performance and long service life

Large crushing ratio, can be used for coarse, medium and fine crushing of materials, saving investment

Better cubic shape of the discharge material without tension and cracks

Simple structure, easy maintenance and low energy consumption, high production efficiency

Impact crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at a high speed. When the material enters the action area of the plate hammer, it will collide with the plate hammer on the rotor and be broken, and then be thrown to the counterattack device to be broken again, and then it will be broken again from the counterattack lining plate. It bounces back to the action area of the blow hammer to be broken again. This process is repeated. The material enters the first, second, third and counterattack chambers from large to small for repeated crushing until the material is broken to the required particle size and discharged from the discharge port.

CHAT ONLINE

CHAT ONLINE

| Model | Size of Feeder Opening(mm) | Max.feeding | Moter(kw) | Roter size(mm) | Capacity(t/h) | Overall Dimension(mm) |

| PF-1007 | 400*730 | 300 | 37-55 | Φ1000*700 | 40-60 | 2400*1560*2660 |

| PF-1010 | 400*1080 | 350 | 55-75 | Φ1000*1050 | 60-90 | 2440*2250*2630 |

| PF-1210 | 400*1080 | 350 | 110-132 | Φ1250*1050 | 80-130 | 2700*2340*2900 |

| PF-1214 | 400*1430 | 350 | 132-160 | Φ1250*1400 | 120-180 | 2700*2690*2890 |

| PF-1315 | 860*1520 | 450 | 180-260 | Φ1300*1500 | 180-230 | 3100*3280*2670 |