limestone,pebble,coal,dolomite,granite,basalt,iron ore,silica sand

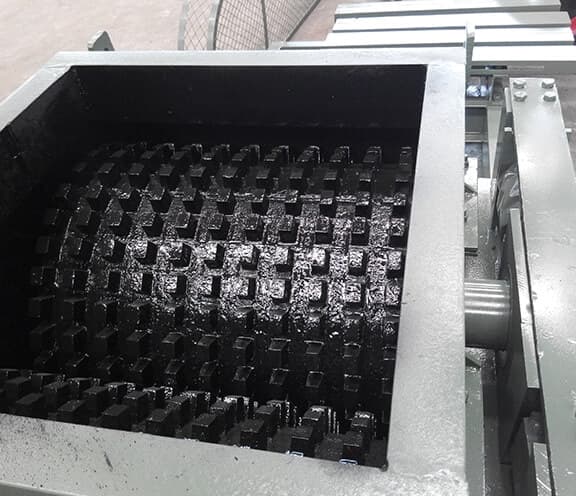

Double teeth stone roller crusher machine series are designed to be used in the industrial branches of ore dressing.chemical engineering,cement,building material.steel industry for medium and fine reduction of various ores and rocks with the hardness below medium level.This type of machine is mainly composed of frame,housing,roll axle,spring,transmission section.It is driven by two motors and two belt wheels.The two rolls are driven by motor v-blets and gears and rotate in opposite direction for crushing material.The space between two rolls is adjustable at a given range for proper control of discharge.

It's available for ore dressing, chemical, cement, refractories, abrasive, building materials industries;

Roller crusher has the more excellent effect than general stave machinery;

Finely crushing all kinds of ore and rock below the high, medium hardness,which can make the minimum grain size below 100 mesh;

Roller crusher is stable operation, easy maintenance, low cost, output size adjustable.

The two sets of individually driven roller shafts are used to crush the material by the crushing force and the shearing force generated by the relative rotation. After the material enters into the crushing chamber, it is subjected to the force of the rotating roller shaft and forced to pass between the two rollers. At the same time, the material starts to be broken by the crushing and shearing of the roller shaft. The broken small particles move along tangent of the rotation roller and been thrown under the machine through the gap between the two rollers.

CHAT ONLINE

CHAT ONLINE

| Model | Roller dia(mm) | Roller length(mm) | Feeding size(mm) | Discharging size(mm) | Capacity (mm) | Feed opening size(mm) | Motor power(kw) | Overall dimension(mm) | Weight(kg) |

| 2PG600 | 600 | 400 | <40 | 3-8 | 5-20 | 370*400 | 11*2 | 2555*2490*1050 | 4000 |

| 2PG800 | 800 | 600 | <60 | 3-10 | 15-40 | 600*500 | 22*2 | 3490*2884*1035 | 7500 |

| 2PG1000 | 1000 | 700 | <80 | 3-12 | 20-50 | 700*600 | 30*2 | 4398*3354*1190 | 12000 |

| 2PG1200 | 1200 | 750 | <90 | 3-14 | 30-80 | 800*600 | 45*2 | 4574*3653*1478 | 17000 |

| 2PG1500 | 1500 | 800 | <100 | 3-15 | 40-100 | 800*800 | 75*2 | 4832*4037*1765 | 27000 |

| 2PG1800 | 1800 | 800 | <130 | 3-18 | 60-130 | 800*800 | 90*2 | 5645*3850*2092 | 30000 |