Solid materials such as coke, coal, ceramic raw materials, quartz stone, limestone, feldspar, water slag, gypsum, clay, salt, chemical raw materials.

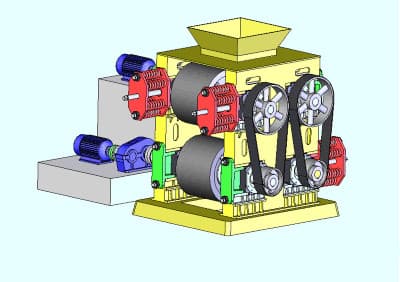

Four roller crusher is the use of four high-strength wear-resistant high extrusion pressure and shear relative rotation of the crushing roller to crush the material into the top two rollers (V-type crushing chamber )later,after the relative rotation of the intermediate two rollers the squeeze pressure,squeeze the material for the first time after rolling and biting mill (thick broken),then enter the relative rotation of the intermediate two rolls ,use the middle two rolls of the pressing force and engages a second squeeze rolling mill (fine break) after finally entering the next two rolls,again using the following two third squeeze roller mill (ultra-crushing)and after (only for four rolls three broken model) to the desired size and then broken sent by the transport equipment.

High efficiency, good performance, simple structure, low noise.

Easy maintenance. the rollers' surface adopts anti-abrasive welding rod or exchangeable dental plate, the maintenance is simple

Low cost and high efficiency, in addition to roller skin, no wearing parts.

Four roller crusher gives a very fine product size distribution and produces very little dust or fines.

The Four roll crusher is the use of four high strength wear resistant alloy grinding roller, relatively high extrusion pressure and shear force produced by the rotation to the broken material. The material into the top two roller V after crushing cavity, extrusion effect by two rollers relative rotation on, for the first time after extrusionand tooth grinding (coarse broken) material, and then into the relative rotation in the middle of the two roller, use the middle two roll extrusion for secondary extrusion and tooth grinding (crusher), the last into the next two roller, using two roll under the third extrusion again, cut and tooth grinding (super finely) after (only applicable in four roll three broken models) broken need granularity by conveying equipment.

CHAT ONLINE

CHAT ONLINE

| Model | Feeding size(mm) | Discharging size(mm) | Capacity(T/H) | Motor Power(kw)(Light weight;Heavy) | Protect method | Diving method |

| 4PG0404PT | <20 | 0.1-10 | 2-30 | 7.5(11);11(15) | Spring | Couplings or V-belt |

| 4PG0605PT | <40 | 0.1-15 | 5-60 | 22(30);30(37) | ||

| 4PG0806PT | <40 | 0.1-20 | 8-90 | 30(37);37(45) | ||

| 4PG0809PT(Y) | <60 | 0.1-20 | 12-120 | 37(45);45(55) | Spring or hydraulic | |

| 4PG0812PT(Y) | <60 | 0.1-20 | 20-180 | 45(55);55(75) | ||

| 4PG1012PT(Y) | <80 | 0.1-30 | 30-220 | 55(75);75(90) | ||

| 4PG1212PT(Y) | <90 | 0.1-40 | 45-320 | 75(90);90(110) | ||

| 4PG1216PT(Y) | <90 | 0.1-50 | 55-400 | 90(110);110(132) |