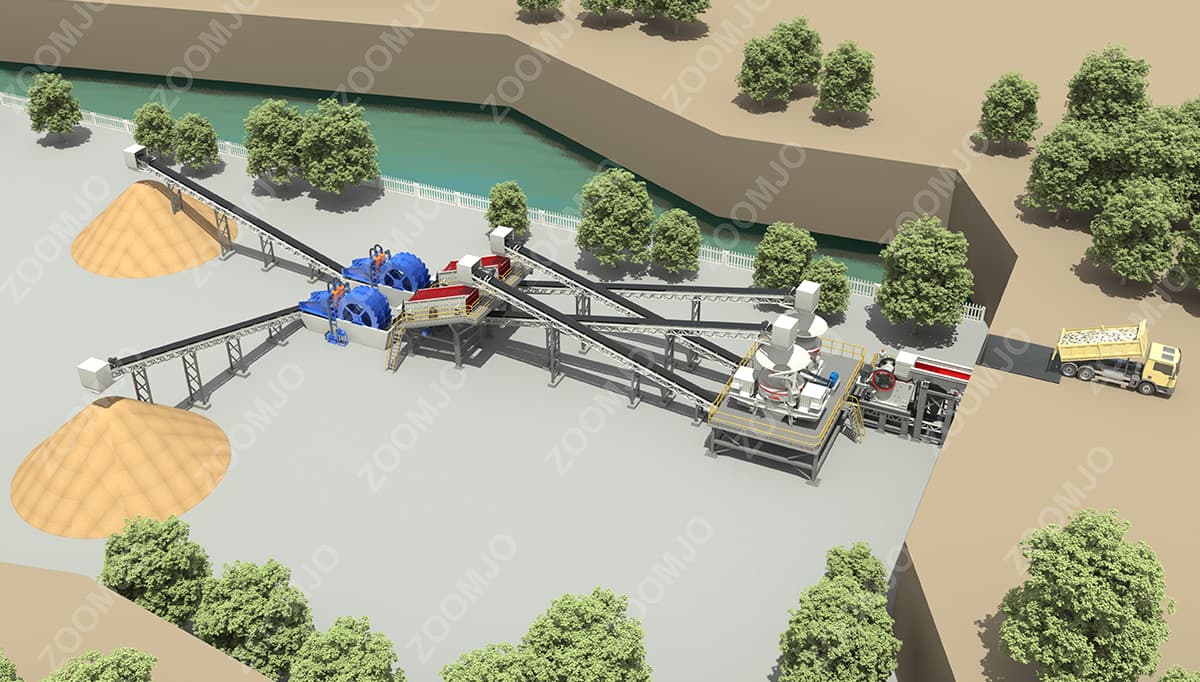

1. Raw basalt is fed into a 50m³ rice silo by truck or loader.

2. The vibrating feeder evenly transports the raw materials in the silo to the jaw crusher

3. The jaw crusher crushes the raw materials below 500-800mm to about 80-200mm, and is transported to the vibrating screen by the belt conveyor. The vibrating screen sieves the materials that meet 0-5mm and transports them to the sand washing and fine sand recovery integrated machine. After cleaning Delivery to the finished product stack.

4. The bulk materials screened by the vibrating screen are conveyed to the multi-cylinder hydraulic cone crusher by the return belt.

5. The multi-cylinder hydraulic cone crusher crushes the material to 16-64mm mixture, which is transported to the vibrating screen by the belt conveyor.

6. The vibrating screen sieves the mixed materials through the aperture of the screen. The materials that meet the requirements of 0-5mm are transported to the sand washing and fine sand recovery integrated machine, and the materials that do not meet the requirements are transported to the sand making machine by the conveyor. The material will return to the vibrating screen to screen the material.

ZOOMJO GROUP located in Henan Province of China. Founded in 1995, Zoomjo has 27years experience,and it is the header of the mechanical industry in China. It has advanced factory technology and excellent trade capabilities. As a modern large-scale production enterprise in the construction machinery base, Zoomjo has a professional design team and an excellent tech skills group. Providing the advanced producing equipment and perfect after-sale service is Zoomjo’ corporate purpose.